Many excellent accomplishments have occurred in woodworking pieces over the years. Woodworking has allowed people to build a lot of buildings, simple tools, toys and a myriad of other things. Having the creativity and foresight to create items with wood is great, it does require some knowledge. Read this article to gain some insight into woodworking that will help you want to learn more about woodworking.

Safety must be a priority when you are doing any time of woodworking project. Always use your tools in the way they were intended to be used and wear safety equipment to avoid injury. Don’t take the guards off a tool – they’re intended to keep you have as they were put there for your protection. You don’t want to begin a project and end up in the hospital.

Try using a stair gauge as a crosscut guides. Then mark where the notches are.You have a great crosscut guide for your circular saw when you put it on the carpenter’s square.

Try creating your own reusable sanding blocks. Cut six 3/4″ pieces of plywood for each sandpaper grit. They should be 2.5″ x 4.75″. Put spray adhesive on the blocks and the tile square. Stick one block to your cork and be sure to cut your cork flush using a utility knife. Apply a bit of adhesive to a sheet of sandpaper and place it onto the cork blocks facing down. Trim your sandpaper so that it is even with the corks and label each block appropriately.

Select an appropriate sort of wood for your projects. Some woods will break upon exertion.

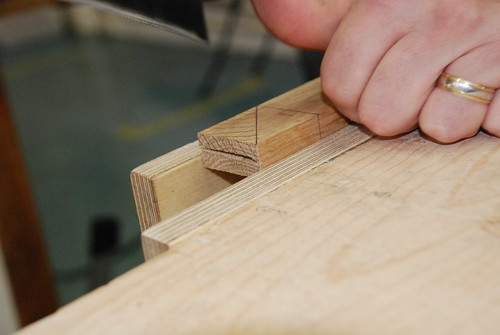

Do not use your fingers as guides when you cut narrow strip of wood into the saw. Use a strip of thin wood instead to maximize safety. This will prevent you won’t chop off a finger.

Tin Snips

Never use your hand to guide wood through a cut! Instead, a long and thin piece of scrap wood should be used to push your piece through your saw. This makes sure that you won’t chop off a finger.

Use tin snips to cut laminate that you are working with laminate. Tin snips let you to quickly and effortless cut laminate into usable size. Using tin snips only for this laminate also helps keep them sharp.

Know your wood’s properties before you buy or use it. The proper wood helps your project comes out how you want it to.

Add spring to your hand grip. These clamps can be very difficult to open with a single hand. There are ways to make it easier.Prior to beginning a glue-up, be sure to arrange all necessary clamps on a piece of scrap wood first. This will have them easy to reach and ready to go so that you can easily use them with one hand.

Prior to applying glue, attempt a dry fitting. Trying to move things around once the glue is on is likely to result in harm to the final project. A dry-fit will give you a good idea of what components go where.

Are you having trouble reaching that out of the way and your hand to fit simultaneously or comfortably? Your toolbox contains the answer! Get a screwdriver with a long handle and pick up a socket that is 12 point.

Try to find wood you can use. Many places will get rid of scraps that could prove quite useful for your project. Flooring stores and construction companies toss old wood. Look around and get pieces of wood that you may need. You can save hundreds of dollars this too.

Make sure that you understand them and that they are not missing information.If they don’t seem to make sense to you, ask at a local hardware store for advice.

It’s important to know the wood’s characteristics before you start working with it. Wood designated as “paint grade” is lower in quality and not suitable for staining. Similarly, particleboard and veneer are very different; veneer does not always absorb enough stain, while particleboard absorbs too much. Getting the correct kind of wood will help you be sure that you can expect good results.

Drinking beer and woodworking may seem like fun. But it is never do that while using saws.Avoid drinking alcohol when working with woodworking tools. This is also true when it comes to illegal drugs or prescription drugs.

Stay in touch with others. Your woodworking shop likely is your personal space and not even have the Internet. There will still be times you get stuck on a tough time with a project. You will never have a problem somebody else hasn’t had before you and asked about.

Enjoy your yard more thanks to your woodworking skills to the test. You can build yourself something like an attractive doghouse or bird feeder. The birds that visit will keep insects away while you work on your yard. If woodworking is something you want to do professionally, think about meeting clients on the deck you built so they can see what you are capable of.

Before sawing, ensure that the blade is in top condition. Dull blades can make simple sawing nearly impossible. It will also increase your chances for error, which could cost you money in the end.

Take your time and watch the various woodworking programs available on television. These shows offer you tips and ideas to take your projects to the next level. Check your TV guide to learn when these shows are on.

Plan a budget for your woodworking budget.Find out how much materials will cost before you start the project.Figure out the cost for everything you need and what it will need. You wouldn’t want to have to bow out of a project down the line because it is too expensive to continue.

Always use sharpened blades when using table saws and skills saws. Dull blades can cause of most accidents in your work area. Wood is more likely to spring back if you are cutting with a dull blade. This has been the cause lots of many workshop accidents.

Always use the recommended size nail for your job. Too large of a nail can split your wood, resulting in it not holding properly. Conversely, if the nail is too small, it can’t penetrate deep enough in the wood to hold these pieces of wood together. Make sure you understand what size nail is correct.

Woodworking does not get the recognition it deserves from consumers. Most people look at a chair and see themselves sitting in it. The woodworker looks at a block of wood and sees the chair. The information above will help you become an expert woodworker.

Tags: cut laminate, tin snips